AC·Magnetisation

Measurement frequency range 10 Hz to 10 kHz; AC magnetic moment resolution, 2-8 emu @10 kHz; 5-point / 3-point metering for high-precision AC magnetisation measurement;

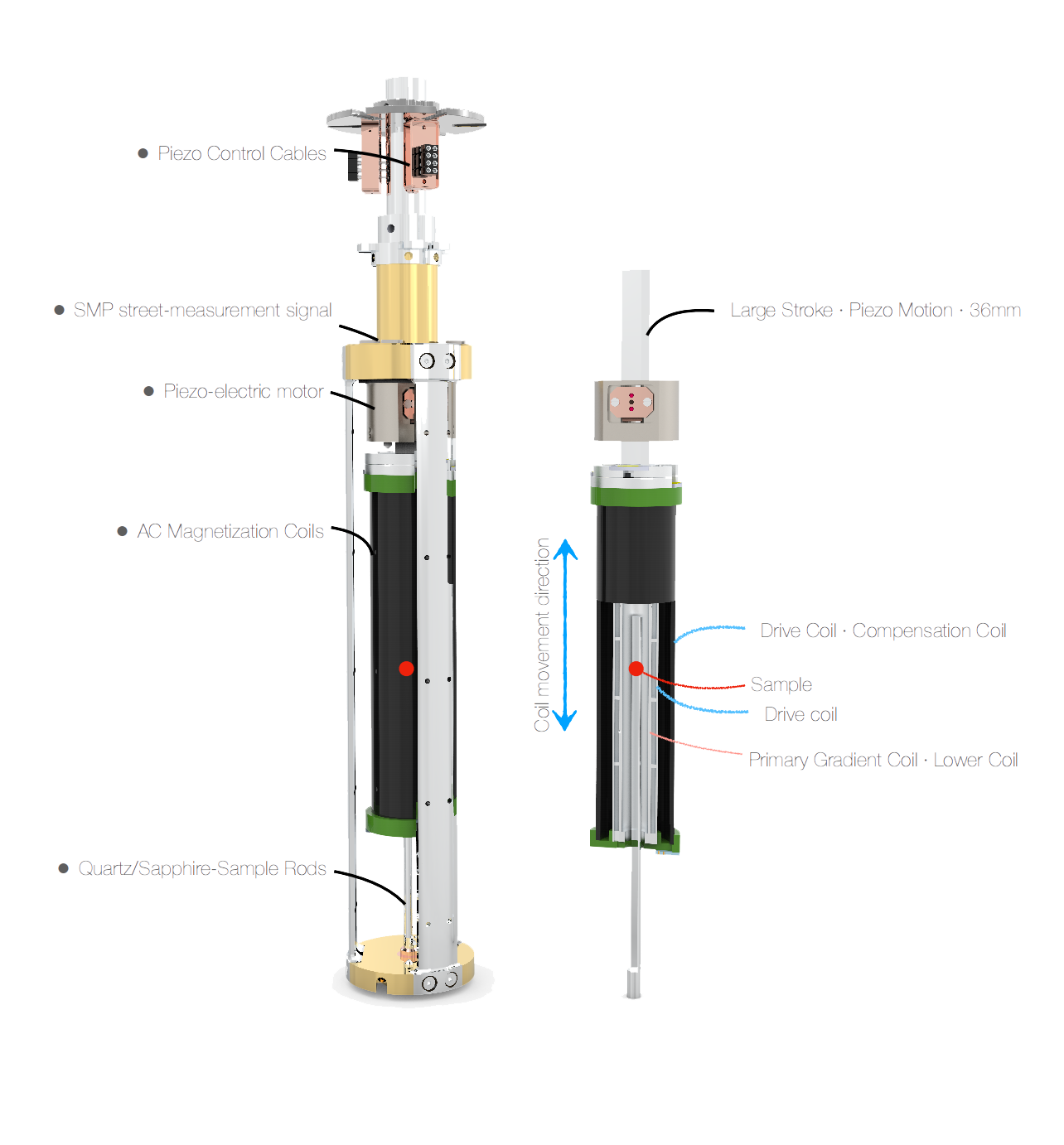

The coil pack consists of a drive coil pack, a probe coil (gradient coil) and a calibration coil;

Multifield Technology· customised piezoelectric shield, “Motion + Detection” at the same time in a low-temperature and strong magnetic environment;;

Because the measurement algorithm requires the sample to be moved three/five times during the measurement process, Multifield Technology has placed the power module directly into a cryogenic environment, rather than the traditional solution of placing the electromagnetic motor at room temperature and carrying the sample through the chamber by means of a 1m-long sample rod.

1. Extremely compact design, supporting sample chamber cryogenic systems by means of a “sample rod”; also supports systems without sample chamber, with direct mounting of the cryogenic end;

Core Measurement Module- Tolerance within 15cm, OD within 25mm;

2. Supports expansion to 300 mK and dilution chiller environments;

No need for room temperature end drive, simple structure; no need for He gas heat conduction, the sample is fixed directly on the cold end without moving; minimum operating temperature of the piezo motor is 30 mK.

The sample position is fixed and the piezoelectric motor moves the “drive/detection-coil set” by 3 – 4 cm;

Relative movement of the sample in the probe coil is achieved by using a piezoelectric motor to drive the coil pack while the sample remains motionless;

1. The position of the sample remains unchanged to ensure that it is always at the centre of the magnetic field;

With a third-party low-temperature magnetic field platform, highly accurate measurements can be obtained even in narrow magnetic uniformity zones (e.g., 1cm);

2. No He gas thermal conductivity is required, and the sample temperature is equally stable even in high vacuum environments;

Since the sample position does not move, you can directly use good thermal conductivity materials such as Sapphire or high purity copper as sample connecting rods to connect directly to the cold end to ensure thermal conductivity efficiency.

Compatible with third-party cryogenic strong magnetic field platforms;

·System components

Piezo Motion Module

1.The body is non-metallic & non-magnetic,

·The main body is non-metallic frame to ensure no crosstalk in AC magnetic field;

·Compatible with low temperature & strong magnetic field & ultra-high vacuum;

2.Customised – powerful sports performance,

·large travel distance 40 mm;

·Real-time position sensing, 1um repeatability;

·Ultra-strong load to ensure operation in strong magnetic field;

3.Extended Upgrad,

·Supports motion control feedback at 30 mK;

Coil Pack·Coils

1.Drive coil,

·AC magnetic field – max. 10 Oe;

·Drive frequency – 10 Hz to 10 kHz;

·Double layer coils – guaranteed 40 mm AC magnetic field uniformity zone;

2.Detection Coil,

·Gradient Detection Coils

3.Calibration coil,

·Calibration coils for calibrating AC magnetisations;

Material Characterizatioin

1.Insulated & high thermal conductivity & non-magnetic material.

·Sapphire, high purity quartz fine rod;

2.Bottom active temperature control,

·With cryogenic thermometer and heater module

·Sample throughout

MultiFields

China

Huairou District, Beijing

Building 2, Nonferrous Metals New Materials Science Park, Huairou Science City, Huairou District, Beijing

Tel:(+86) 186 0055 3105

Wechat:186 0055 3105

Websites:multi-field.com

Email:info@multi-field.com